Pantex Blog

Pantex 2018 Armed Forces Day Celebration

Pantex recently held its annual Armed Forces Day celebration to recognize and thank veterans and active military members for their service in support of our country. The ceremony featured presentation of the colors by the Pantex Fire Department Honor Guard, recognition of the POW/MIA table, and a keynote address by Lyle Cary, CNS vice president for Safeguards, Security, and Emergency Services.

Pantex hosts Partners in Excellence Forum

Pantex hosted a Partners in Excellence Outreach Forum attended by representatives from 61 companies looking to do work with CNS.

Small Business Program Manager Ryan Johnston said, “Pantex must have a broad base of contractors to partner with to ensure mission success. The forum provided local and national contractors the knowledge needed to establish these partnerships.”

Discussion included upcoming opportunities for construction related scopes, an overview of the site, and how to do business with CNS.

Fellows Colloquium, a historic day for CNS

CNS hosted its inaugural Fellows Colloquium March 28 at Y 12, and CNS President and CEO Morgan Smith called it a historic day. The forum was established to highlight CNS’s vital technical work and to honor its first four fellows for their vast technical knowledge and their abilities to mentor others.

“This is our declaration that we are an organization that does work of tremendous scientific and technical significance for our nation, and this work requires the very best. It’s our most senior scientific and technical rank or title and connotes that we are engaged in activities that merit this level of personnel — equal to what occurs elsewhere in high technology industries,” said Smith.

Glenn Pfennigwerth (Uranium Fellow), Alan Moore (Metallurgy), Vincent Lamberti (Y 12 Surveillance), and Lorelei Woods (Pantex Surveillance) were recognized as our strategic advisors and top mentors and were pinned by Smith. With a combined 143 years of experience, these fellows set the bar high. Each fellow presented the state of their area of expertise, and 18 other Pantex and Y 12 technical experts presented posters covering diverse areas of expertise — from explosives and advanced manufacturing to nonproliferation and lithium.

“The colloquium was vitally important to showcase the great technical work we do and to honor the individuals who are leading us into the future,” said Ashley Stowe, CNS Fellows program manager. “The excitement for staff at Pantex and Y 12 encourages me as we move forward and continue to grow an excellent technical staff. This is just the beginning, however; we are already looking forward to hosting the 2019 colloquium at Pantex.”

Leadership Amarillo visits Pantex

The Leadership Amarillo Class of 2017/2018 recently visited Pantex. After a history overview, the group visited a weapon display and a security bearcat vehicle display. The community leaders also experienced an explosive demonstration at the firing site.

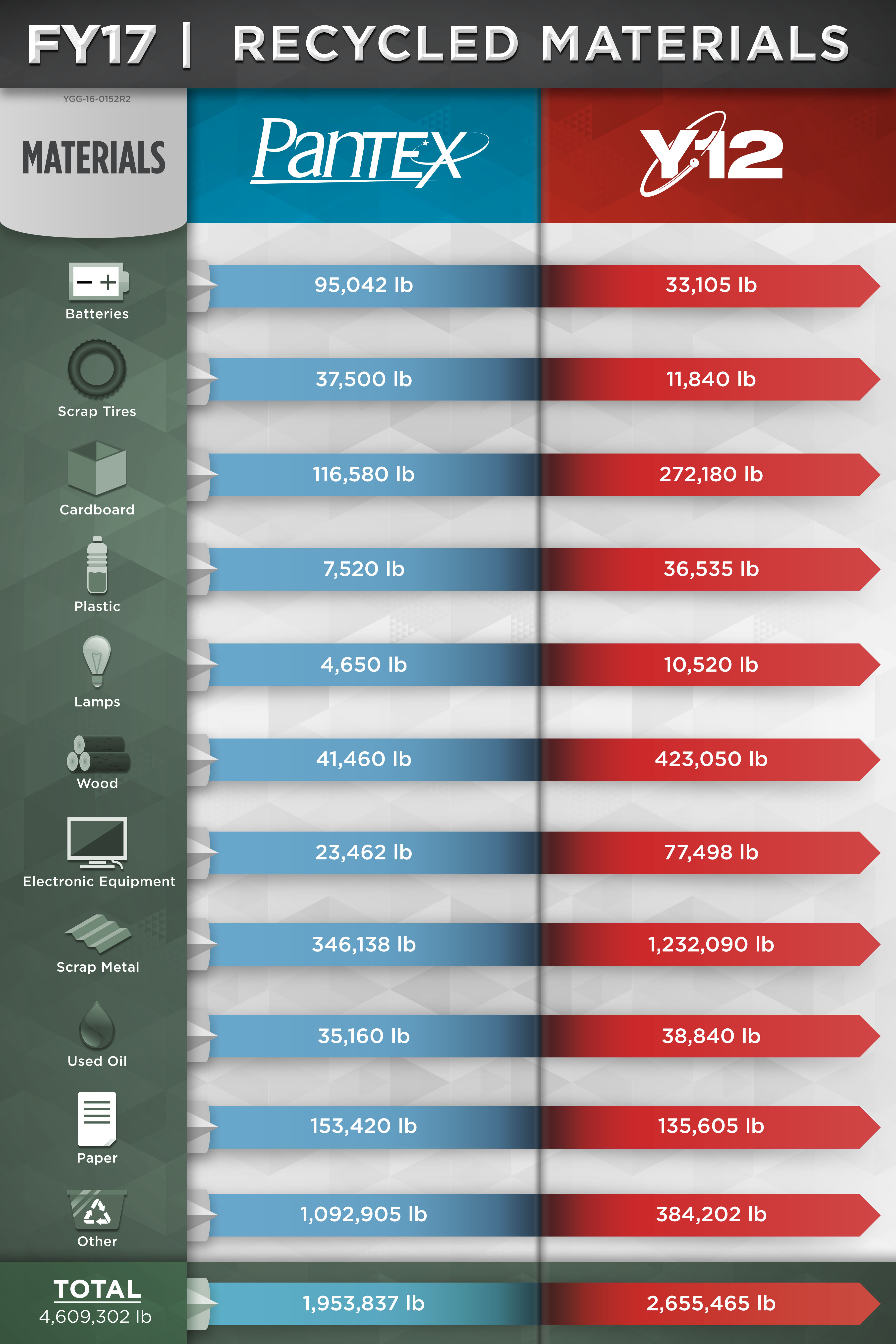

Celebrating Earth Day every day

There is no Planet B, so Consolidated Nuclear Security, LLC focuses on recycling everything from regular office paper to electronic equipment and scrap metal. In Fiscal Year 2017, employees at Pantex and Y-12 recycled more than 4.6 million pounds of materials, demonstrating their commitment to environmental stewardship.