Pantex Blog

Pantex Earth Day efforts – maintaining sustainability

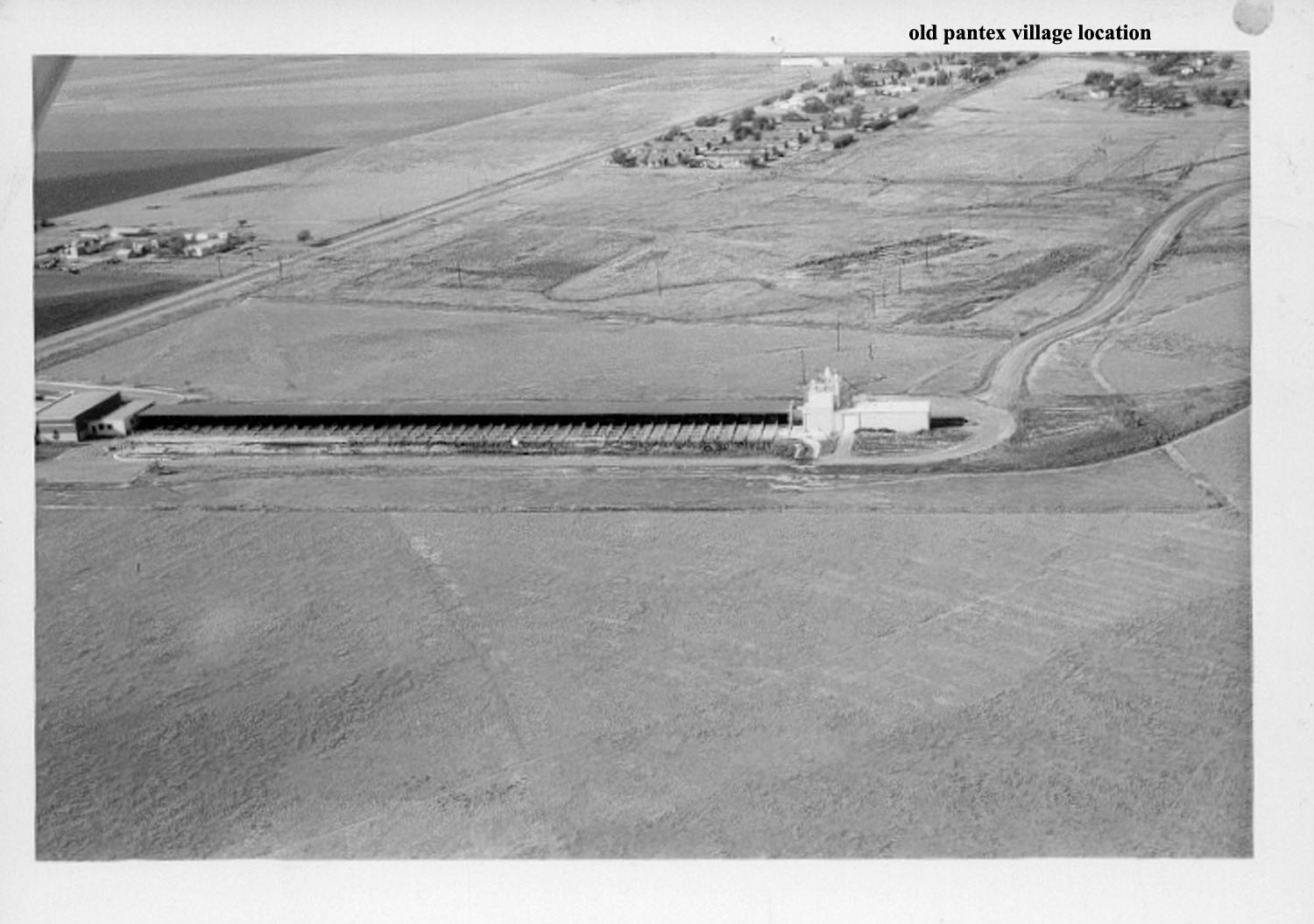

New retention pond at Pantex will hold 8 million gallons of beneficial recycled water to be used for 600 acres of crops at the Texas Tech University Research Farm.

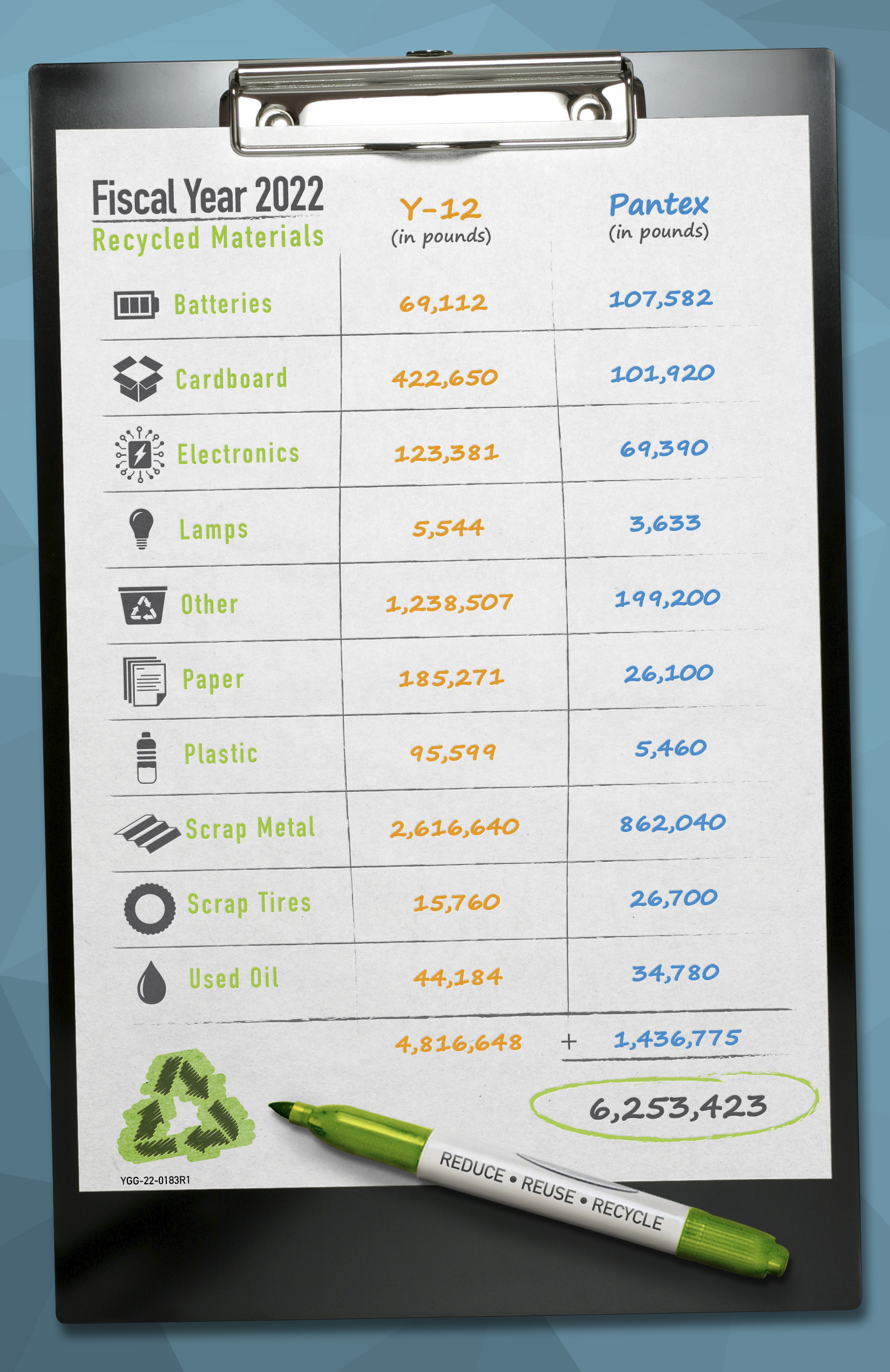

Sustainability is the key word when it comes to CNS's efforts in recycling and being a good environmental steward.

Tracy Griffiths, Pantex’s new Environmental Science senior associate, is working alongside Alicia Barley with Pantex’s Sustainability program to meet some high-level goals on their checklist:

- Reaching carbon pollution-free electric by 2030 (currently, Pantex is at 50%)

- Initiating the fleet electrification program

- Building a net-zero emissions portfolio by 2045, and creating a 50% emissions reduction by 2032

- Developing climate-resilient infrastructure and operations

- Assisting making our Environmental Management System a business management system to support the achievement of DOE sustainability goals

“To me sustainability is so important because it is an additional way to preserve the Earth for future generations, by slowing down the affects that humans are having on the environment and climate,” said Alicia Barley, Environmental Sustainability Specialist and EMS Coordinator. “It’s easy to think that the small things don’t matter like recycling a water bottle, or reusing that water bottle instead of grabbing a new one but these small acts really do add up especially at a site as big as Pantex.”

When it comes to Pantex’s recycling efforts, one of the biggest projects focuses on water, actively remediating its underground water. Combined with treated wastewater, water will be sent through a pipeline to the adjacent holding pond, currently under construction.

When completed, the new retention pond will hold 8 million gallons, which equals about 12 Olympic-sized swimming pools. Using a Pivot Irrigation System, about 600 acres of crops will receive the treated wastewater for beneficial reuse on land located east of FM2373 that is owned by DOE. Since the start of remedial efforts at Pantex over the last few decades, more than 1.7 billion gallons of water have been beneficially reused … enough to fill the Dallas Cowboys AT&T Stadium twice.

Since the water reclamation system contains no fish, the indigenous tiger salamander takes advantage of a predator-free environment, laying eggs in the recycled water system. The eggs hatch into larvae known as “water dogs,” and over the next few months, they sprout hind legs, lose their gills, and are able to leave the water. Some, however, become “neotenic”—sexually maturing, but maintaining their larval form. They become enormous, develop teeth, and become cannibalistic, eating salamander larvae, all because of Pantex’s water reclamation efforts and maintaining a delicate balance in the environment.

Adult “neotenic” salamander found at Pantex.

Adult tiger salamander found at Pantex.

“It’s an exciting time to be in Sustainability because we are right at the cusp of big things in renewable and clean energy, electric vehicles and greenhouse gas reduction. As a DOE site we get the privilege to be leaders in the sustainability realm and start moving toward a cleaner future,” added Barley.

The layers of the Pantex Sustainability program cascade, linking to just about every program in some way; millions of pounds of refuse that never makes it to a landfill, driving emissions-free vehicles, water recycling that benefits not only crops, but also indigenous wildlife. All due to reaching and sustaining--- sustainability.

Why we buy sustainable products

Brad Russell, the Sustainable Acquisition Program manager, wants employees to know buying green is more than a saying; it is a way of life at Pantex and Y-12.

As a government contractor, Consolidated Nuclear Security is required to abide by government regulations. One requirement is purchasing sustainable products, which provides opportunities for CNS to make positive choices for the environment.

CNS's newest Sustainable Acquisition Program manager, Brad Russell, is one of those experts guiding those purchases. “It is great when CNS and the sites are recognized for the outstanding work they do in achieving sustainability,” Russell said.

According to Russell, when CNS purchases sustainable products, “we’re not only making better choices, but we’re showing CNS's commitment to our environment. Purchasing sustainable products helps to establish a healthier environment for employees because we’re eliminating products that off gas, like cleaning products, flooring, and paint; reducing the amount of hazardous material on site; and reducing atmospheric carbon dioxide that causes climate change.”

It all adds up because the federal government is the single largest consumer in the world. “Federal sustainable purchasing is a big business,” Russell said. “Products range from remanufactured toner cartridges, post-consumer 100% recycled content paper, green electronics, bio-based cleaning products, compostable or biodegradable food containers, and non-toxic construction material.”

GreenBuy Award Winners

Congratulations to Pantex and Y-12 on each receiving a GreenBuy Award for purchasing achievement in FY 2022.

Pantex received the silver level for purchasing six priority products in four categories.

Y-12 received the gold level for purchasing 10 priority products in six categories.

This fiscal year, Russell and his program have set several goals, including increased purchasing of bio-based and recycled content. “In FY23, we want to introduce at least ten new sustainable products, issue a user-friendly quick reference guide that highlights sustainable products readily available, and replace some flooring [at Y-12] with sustainable flooring.”

When looking to buy products, at work or at home, Russell encourages checking out the product description. “Most items have a description that tells you if it is bio-based or made with recycled content,” he said.

The team tracks purchases of sustainable products at Y-12. “We like to know if you liked it, did not like it, and why. This information helps us in recommending products for future users as well as providing feedback to our vendors.”

The data collected on purchases is also used to track how well CNS and its sites do in meeting those government expectations and to show how the program has grown. Both Pantex and Y-12 have received several awards for purchasing sustainable products, with the U.S. Department of Energy GreenBuy Awards being the most recent example. This program recognizes DOE sites for excelling in their “green purchasing” and going above compliance requirements.

“Being recognized by DOE shows they recognize CNS goes beyond the requirements. The Sustainable Acquisition Program is here to make a difference and figure out what purchases can change and be more sustainable,” Russell said. “Submitting award nominations and being recognized for our efforts is really rewarding.”

I am mission success: Tony Biggs

Meet Tony Biggs, Pantex Environmental Projects manager, who has more than 30 years of service and has seen a variety of successes during his time as a Pantexan.

Take 5 minutes and learn about CNS’s Tony Biggs, Pantex Environmental Projects manager. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

It’s not that uncommon to find Pantex coworkers who have multiple decades of service along with low badge numbers. In case you don’t know him, please meet Tony Biggs with 34 years of service, badge in the 9000 range, and the current title of manager of environmental projects — not too shabby for a one‑time unemployed scientist.

“I was an out‑of‑work petroleum geologist when offered the job at Pantex,” recalled Biggs. “However, instead of chasing subsurface oil deposits, I ended up chasing contamination deposits in the soils and groundwater.”

For years as department manager, Biggs has led environmental projects, including finding innovative ways to remediate environmental concerns.

“Our staff oversees environmental construction projects, maintains and operates remediation systems, samples environmental media, and oversees contract laboratories analyzing our samples. All of this work is to address the environmental contamination resulting from legacy wastes of the Cold War era.”

Two of Biggs’ most memorable projects focused on soil cleanup both on‑site and to the southeast of Pantex.

“Back in the mid‑1990s, I managed a project to identify and clean up soil contamination in ditches by collecting the samples with a drilling rig, analyzing the samples within a couple of days using a mobile on‑site lab, determining what soil needed to be removed, and excavating and shipping the contaminated soil for disposal. It was quite a show. The prime subcontractor had talked to a couple of transportation companies, and there was a miscommunication. Both transportation companies thought they had the job and sent dump trucks. There must have been more than 50 parked down 15th Street waiting to go to work. The trucks were lined up from the traffic light and around the bend toward Building 12‑103. That was quite a sight,” recalled Biggs.

The more recent project centered on the cleanup technology known as bioremediation, removing legacy contaminants that had moved offsite to the southeast, transported within the flow of the groundwater.

“We inject locally sourced molasses down 300 feet into the perched groundwater to feed naturally occurring bacteria. As the contaminated groundwater moves through the wall of bacteria, the contaminants are broken down until the groundwater is clean. Back in the mid‑2000s when Pantex was installing the bioremediation wells, this was cutting‑edge technology, and Pantex was on forefront,” he said. “I believe Pantex has the largest bioremediation system of all the sites within the

But as they say, “all good things,” and after deciding to push back retirement another year, 2023 will be Biggs’s last as a Pantexan.

“My parting advice? Be sure to ‘stop and smell the roses,’” Biggs recommends. “We can get so tied up in meeting schedules, accomplishing work scope, and completing our deliverables that we can fail to see what we have accomplished. We’ve done some cool stuff!”

Why are you mission success? “Managing an incredible group of people that performs the cleanup requirements of Pantex’s state and federal permits and allows the operations at the Plant to continue.”

Describe how your career compares or contrasts to your expectations. “Since college, I knew I didn’t want to be stuck behind a desk 24/7. Early in my career, most of my work was outdoors; now most is indoors, so it’s been a nice mix. I couldn’t have asked for a better job!”

What is the greatest strength you bring to your organization? “I had a supervisor once say, ‘My job is to remove the roadblocks so you can perform your job.’ I think I’m doing that for my staff. They are really talented and get the job done.”

As an employee, how do you want to be remembered? “Being fair to my coworkers and staff; my humor — I enjoy injecting humor into meetings and discussions; and the work my group has accomplished cleaning up the environment.”

What would your coworkers be most surprised to learn about you as you plan for retirement? In the past, I enjoyed making my own beer, and when I retire I plan to do more of that. I also used to make my own biodiesel and drive an old Mercedes to work. For retirement, I’ve got to get a camper so my wife and I can go to the National Parks.

JTAs: Testbeds provide vital data to NNSA engineers, military

JTAs: Testbeds provide vital data to NNSA engineers, military.

In September 1992, President George H.W. Bush ended explosive testing of the United States’ nuclear arsenal less than 2 weeks after the so‑called “Divider” detonation at the Nevada Test Site. Though few at the time expected it would be the nation’s last live‑fire nuclear test, the Clinton Administration decision 4 years later to sign the Comprehensive Nuclear Test Ban Treaty marked an undeniable turning point in the nuclear weapons era.

Clearly, the end of live testing did not end the U.S. nuclear weapons enterprise. Today’s weapons are significantly more advanced than those of the Cold War. However, without actual detonations, how is Uncle Sam to keep his nuclear spear honed for a battle he hopes never to fight?

One key answer to that question lies in three simple words: Joint Test Assembly.

“JTAs are nuclear explosive look‑alikes,” Production Manager Curtis Chamberlain said.

These mock‑ups look and respond like a completed weapon, but lack a physics package and other components. What they do have, Chamberlain explained, is the ability to record and/or transmit telemetry that feeds valuable data to National Nuclear Security Administration scientists and engineers. Without the risk to human life or the environment associated with a nuclear blast, JTA flights augment virtual testing which drives the modernization and lifetime‑extension programs at Pantex and NNSA labs elsewhere.

Following assembly by teams of adeptly trained Pantex technicians, each resulting “test weapon” records “how it is doing in flight and that everything is happening according to plan — just how it would in the real world,” Chamberlain said.

After some JTA flights, the assembly may be returned to Pantex for disassembly and recovery of additional performance data.

“The data collected during JTA assembly is strictly focused on surveillance,” said J.D. Harris, a former production manager. “It helps the design agencies with annual assessments to … maintain certification on the weapon program.”

It is a complex, ongoing process that balances the need for an understanding of how devices age, the effectiveness of new modifications, and the given quantity in the nation’s inventory. While JTA testbeds may not produce a proverbial big boom, the impact of their assembly, disassembly, and analysis are just as far reaching.

“There are quality driven tests as part of the assembly process,” Harris confirmed.

One system assembled at Pantex, the B61 12, is the twelfth iteration of a munition that entered service at the height of the Cold War as an unguided air‑dropped nuclear bomb. Another system, the W88, entered the stockpile in 1988 as a submarine‑launched system. Regardless of which system is involved, JTAs are a normal part of a weapon’s life cycle.

Chamberlain and Harris explained that the NNSA lab responsible for a given weapon system — B61 12s, W88 Alt 370s, or any number of others — determines the annual number of JTA flights to conduct. Lab staff then coordinate with the expert technicians at Pantex, ensuring the necessary components are included in each assembly, depending on what functionality each flight is designed to test.

Building and dismantling a JTA requires its own qualification program. For the men and women of these programs, the payoff is knowing that their work allows NNSA officials to assure the president of a secure nation. Occasionally, Chamberlain noted, there might be an additional bonus.

“The reward is that I am sometimes able to send [my team to observe] flights,” he said. “They get to see their product in use.”

Today, thanks to the teamwork and skills of Pantexans and their NNSA colleagues, thoroughly updated and modernized B61‑12 and W88 Alt 370 programs remain vital resources in the nation’s deterrent force.

B61 Mod 12 Joint Test Assembly

Building Pantex City: A village is born

“It takes a village.”

That phrase, echoing a proverb about the emphasis on family and community in raising children, also applies to a time about 70 years ago in the heart of the Texas Panhandle.

In 1943, housing was at a premium in the Amarillo area, and with the war effort and production at Pantex already in full swing, along with a growing workforce, the need for new homes was obvious.

Engineer Ed Groman surveys the northwest boundary corner of the Pantex Housing Project in 1943.

The National Housing Administration (now, the U.S. Department of Housing and Urban Development, or HUD) approved 175 new homes for Pantex employees with three or more family members, but even that was not enough. So, an additional 360 one-, two- and three-bedroom apartments were built.

It was all part of what was then called “Pantex City,” located just north of U.S. Highway 60 and Farm-to-Market Road 683. Along with apartments and homes, the village included plans for a shopping center with a grocery store, meat market, fire station, drug store, barber shop, beauty parlor, shoe repair, and a tailor shop. There was also talk of a possible grade school with plans to bus students back to town for high school.

Site of the Pantex Village

Thanks to pre-fabricated, mass-production methods, construction was slated for completion in April 1943. Dwellings went up like Tinker Toys with each unit comprised of four to eight apartments. An additional 400 pre-fab homes were added, bringing the population of the Pantex Village up to a few thousand. The village grew to 69 residence buildings, a community center, and a store, supporting the approximately 5,325 Pantex employees working three shifts at the height of World War II.

Construction of the pre-fab housing units at the Pantex Village

Before the war’s end, the village was fairly isolated, functioning as a self-sufficient community. It was 10 miles from the town of Panhandle and accessed only through a perimeter gate, which was locked each evening. There were recreational facilities, especially for the younger set; including basketball and tennis courts along with a teen club for dances.

Housing barracks

As a village, there was also a small newspaper called the “Pantex Breeze.” There were no real village officials, as the place was run like a housing project; there was a manager but no one was ever elected as an official to preside over the village. To some outsiders, the village was known as the low-income “Cardboard Village” due to the pre-fab materials and walls so thin you could hear neighbors talking.

In 1949, the plant and village were acquired by Texas Technological College (now Texas Tech University), and by the end of that year, the village was turned over to Carson County. It was still going strong in the early 1950s with apartments ranging from $33 to $42 per month and all utilities paid. After years of rotating chaplains, the Baptist church and Church of Christ moved into permanent buildings within the village early 1950s.

In an article published in the Texas Observer magazine called “Letter from the Panhandle,” noted cowboy poet, author, and former village resident Buck Ramsey reminisced about his time at Pantex.

“On the western edge, the government constructed a village; symmetrical rows of buildings so uniform there was a nightly problem of entering the wrong apartment by mistake. The war industry, with its promise of regular paychecks and dwellings with gas heaters and indoor plumbing, lured many families from the hardscrabble countryside. Mine was among them.”

But all good things come to an end, and in 1968, Pantex Village closed due to the Amarillo Air Base being shut down the previous year and the resulting large number of vacancies caused by improved economic opportunities elsewhere.

Ads were placed throughout the Panhandle announcing that the village buildings were all to be sold at auction. Some of the smaller buildings ended up being sold and are reportedly still being used in the town of Panhandle for storage.

However, the most surprising outcome of the auction can still be found on the east side of Amarillo, on Interstate 40 at one of the city’s most heavily advertised and well-visited tourist destinations. The Big Texan Steak Ranch, famous for its “free 72-ounce steak, if eaten within an hour,” has a surprising Pantex connection.

Owner Bob Lee purchased and dismantled five barracks picked up at the auction and used the lumber to build his restaurant in 1960. Reportedly, most of that wood was lost in a fire in 1976, but the restaurant was rebuilt with the help of 100 of his employees pitching in to help out.

Just like a time more than 30 years earlier… it took a village.